How to TEST the precious metals

To be able to understand limitations, we need to start at a high level and break the entire workflow down into pieces. This lets us understand how it fits into the overall process of developing, testing, manufacturing, and shipping products to customers.

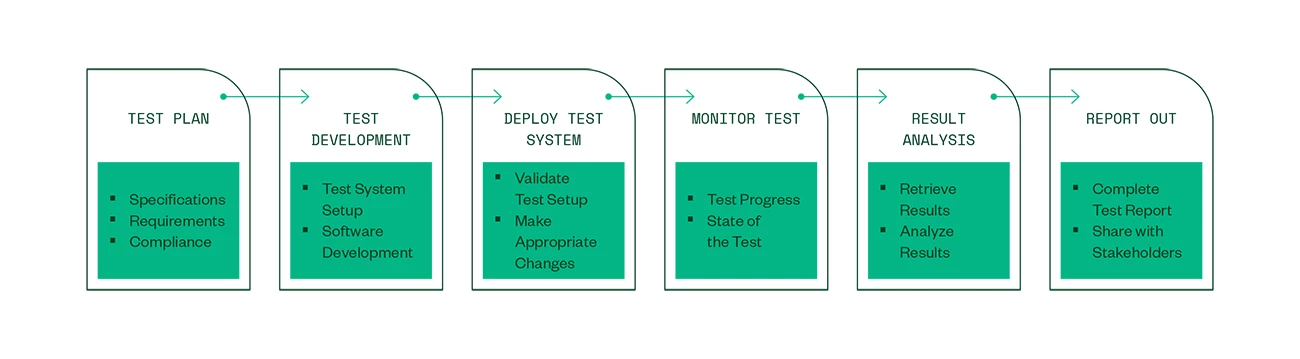

In a typical workflow, V&V engineers get involved and start discussing specifications and requirements with design engineers as the Engineering Validation Test (EVT) stage approaches. Let’s review the high-level steps.

- Create the Test Plan—Gather requirements to see what equipment is needed and which software test routines must be developed. Sign off on test plan and cases.

- Build the Test System—Build systems and develop software.

- Deploy the Test System—Hand off to a technician tasked to deploy and run the test—or the V&V engineer walks over to the tester, deploys the software, and starts the test.

- Monitor Test—Monitor test execution to enable teams to react quickly to an unexpected failure. Since it’s rare to have the resources available to watch the entire progress in V&V, it’s more likely that engineers or technicians will walk over to check as they have availability.

- Analyze Results—Manually transfer results from the tester to the appropriate team for analyzing.

- Report Results—Share outcome with design engineers and other stakeholders.

Depending on whether the product passed or failed, the next step could either be another design iteration and test or it could be handoff to manufacturing for production.

Figure 1. Typical V&V Test Engineering Workflow

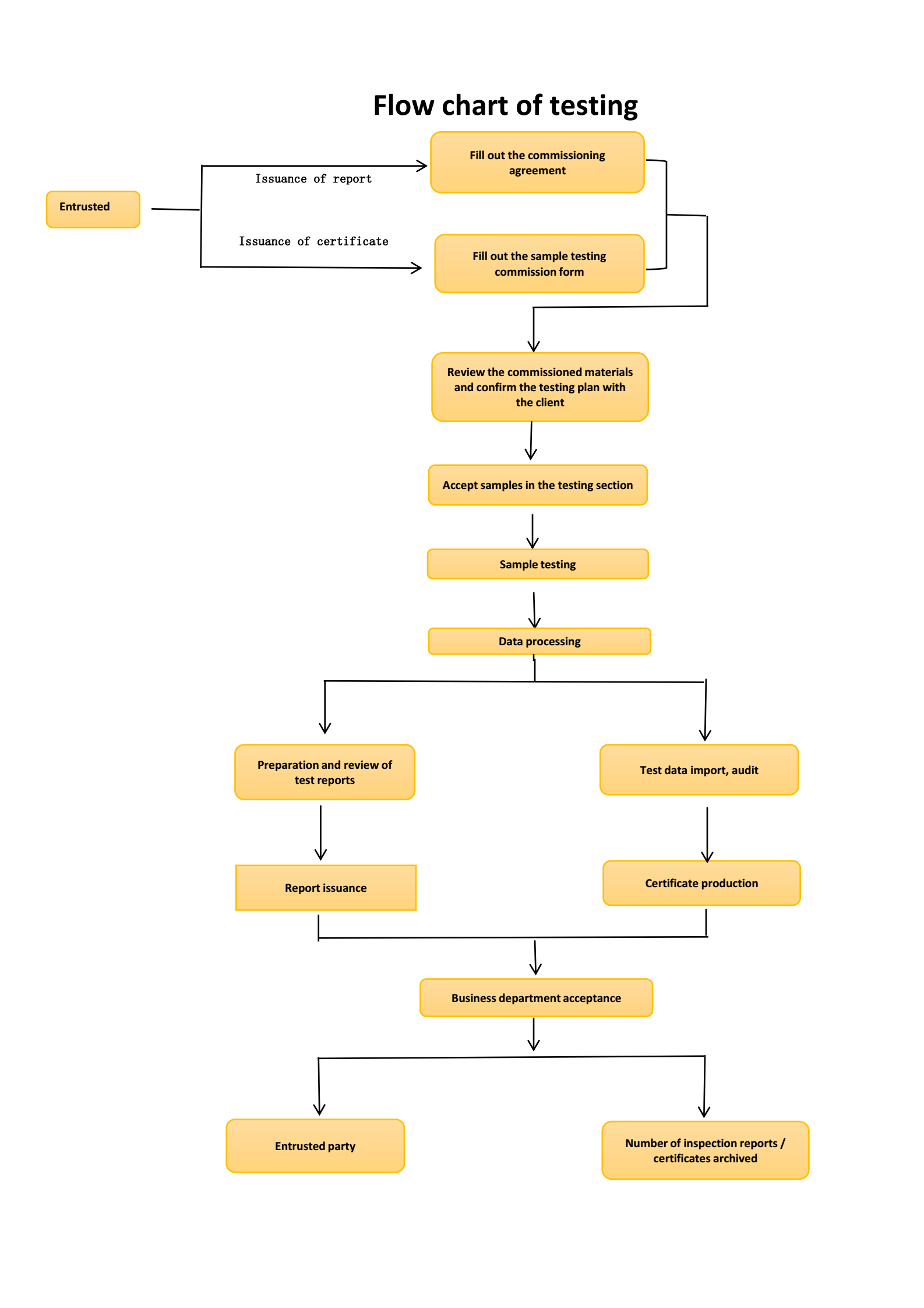

Precious Metals Laboratory Testing Procedures